citygrid

permeable pavers

<p>Discover our Heavy-Duty Permeable Pavers for Ground <br>Stabilization. Made from 100% recyclable plastic. Designed <br>for heavy-duty applications.</p>

Heavy-Duty Permeable Pavers for Ground Stabilization

<h4>Durable Permeable Pavers: Made from 100% recycled/recyclable plastic, these permeable pavers are designed for heavy-duty applications.</h4><p>Fully compliant with SuDS (sustainable urban drainage systems), they are a perfect solution for eco-friendly ground stabilization.</p><p>Benefits of using our permeable pavers:</p><ul><li>Minimize surface water run off</li><li>Reduce flood risk</li><li>Improve water quality</li><li>Encourage biodiversity</li></ul><p> </p>

Download

<figure class="table"><table><tbody><tr><th>Installation Instructions</th><th> <a href="https://www.bg-graspointner.com/_Resources/Persistent/c/7/f/f/c7ff003897b5772643a89baeda85fc02a9d734e5/installation_nstructions_pdf.zip">PDF</a></th></tr><tr><th>Installation Instructions</th><th> <a href="https://www.bg-graspointner.com/_Resources/Persistent/1/4/4/4/14444761a008b12c0cdb19fbea7e91d76b906b9e/installation_nstructions_dwg.zip">DWG</a></th></tr><tr><th> Spec Sheet</th><th><a href="https://www.bg-graspointner.com/_Resources/Persistent/b/6/e/5/b6e534523f327c90ff0a274fca1e1ae45fbe9e43/citygrid_80090401_Heavy_Duty_Permeable_Ground_Grid.pdf"> PDF</a></th></tr><tr><th> Spec Sheet</th><th> <a href="https://www.bg-graspointner.com/_Resources/Persistent/f/7/3/9/f7395f39a1ec13cf3faf385e5edc4a867c6fab83/Citygrid_80090401_Heavy_Duty_Permeable_Ground_Grid.dwg.zip">DWG</a></th></tr></tbody></table></figure>

<h4><strong>OVERVIEW</strong></h4><p>Material: 100% recycled polyolefins<br>Nominal size: (L x W x H) 60 x 40 x 8 cm / 24″ x 15.75″ x 3.15″<br>Unit weight: 9 kg / 19.8 lb (37,5 kg / 82.67 lb per 1 m² panel)<br>Coverage: 4.17 grids/m² or 0.39 grids/ft2 (1 grid = 0.24 m² / 2.58 ft²)<br>Color: Grey<br>Connection type: Tongue and groove<br>Infiltration rate: 2,500 mm/hr for gravel</p><p> </p>

<h4><strong>KEY FACTS</strong></h4><ul><li>High compressive strength</li><li>Flexible and resistant to cracking</li><li>Anti-slip & UV resistant</li><li>Harmless to the environment</li><li>Meet SLW60 loading category (vehicle up to 60 metric tonnes / 66 tons gross weight)</li><li>Within HSE manual handling guidelines</li></ul><p> </p>

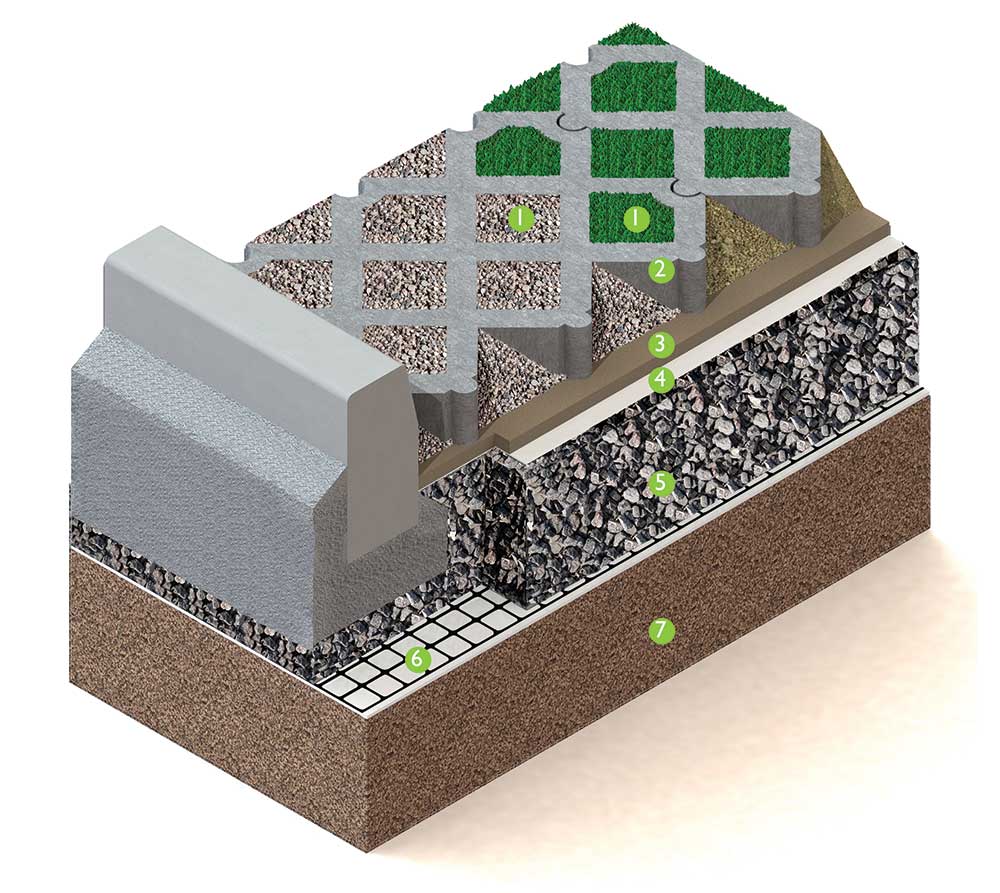

TYPICAL INSTALLATION EXAMPLE Heavy duty permeable ground grid infiltration ![]()

<p><strong>1. Grass seeded or gravel finish</strong><br> </p><p><strong>2. Citygrid units (permeable grid)</strong></p><ul><li>Grass: Good quality, free-draining friable topsoil, seeded at 6 -10 lbs per 1,000 ft² or 35–50 g/m², pre-seeding fertilizer applied.</li><li>Gravel: Clean, free-draining angular crushed rock 0.2 – 0.6″ or 5–15 mm. Do not use rounded or river washed gravel.<br> </li></ul><p><strong>3. Grit bedding</strong><br>Clean coarse 0.08 – 0.25″ or 2–6 mm grit compacted to 0.8″or 20 mm.<br> </p><p><strong>4. Geotextile filtration layer</strong><br>Non-woven needle-punched, minimum 3.25 oz/yd² or 100 g/m2.<br> </p><p><strong>5. Free-draining engineered sub-base</strong><br>Free-draining granular base with a depth to suit the anticipated loading. N.B. Standard granular base is not suitable as it’s not free-draining.<br> </p><p><strong>6. Geotextile separation layer/Geogrid</strong><br>30/30 geogrid on a non-woven needle-punched geotextile, minimum 3.25 oz/yd² or 100 g/m².<br> </p><p><strong>7. Sub soil</strong><br>Establish CBR value to calculate depth of free-draining granular base.</p>

Benefits

<h4>Permeable design</h4><p>A rigid but open cellular design allows the grids to provide both exceptional support and water management.</p><p> </p><h4>High load</h4><p>Meets high SLW vehicle usage specifications, up to 60 metric tonnes (DIN 1072).</p><p> </p><h4>Lightweight</h4><p>Complies with HSE manual handling guidelines.</p><p> </p>

<h4>Application options</h4><p>Open cells can be filled with either gravel or soil and seed depending on your application.</p><p> </p><h4>Environmentally friendly</h4><p>Manufactured from 100% recycled plastic.</p><p> </p><h4>Stable</h4><p>Location fit connection improves stability once units are in position.</p><p> </p>

<h4>Parking markers</h4><p>Standard thermoplastic road paint.<br> </p><h4>Pallet size</h4><p>45” x 46” x 91” (27 layers of 5)<br> </p><h4>Pallet details</h4><p>135 grids, 2,673 lbs / 1,212 kg (16 pallets/load)<br> </p><h4>Compliant with</h4><ul><li>USA: Americans with Disabilities Act</li><li>Canada: Charter of Rights and Freedoms & The Canadian Human Rights Act</li></ul><p> </p>